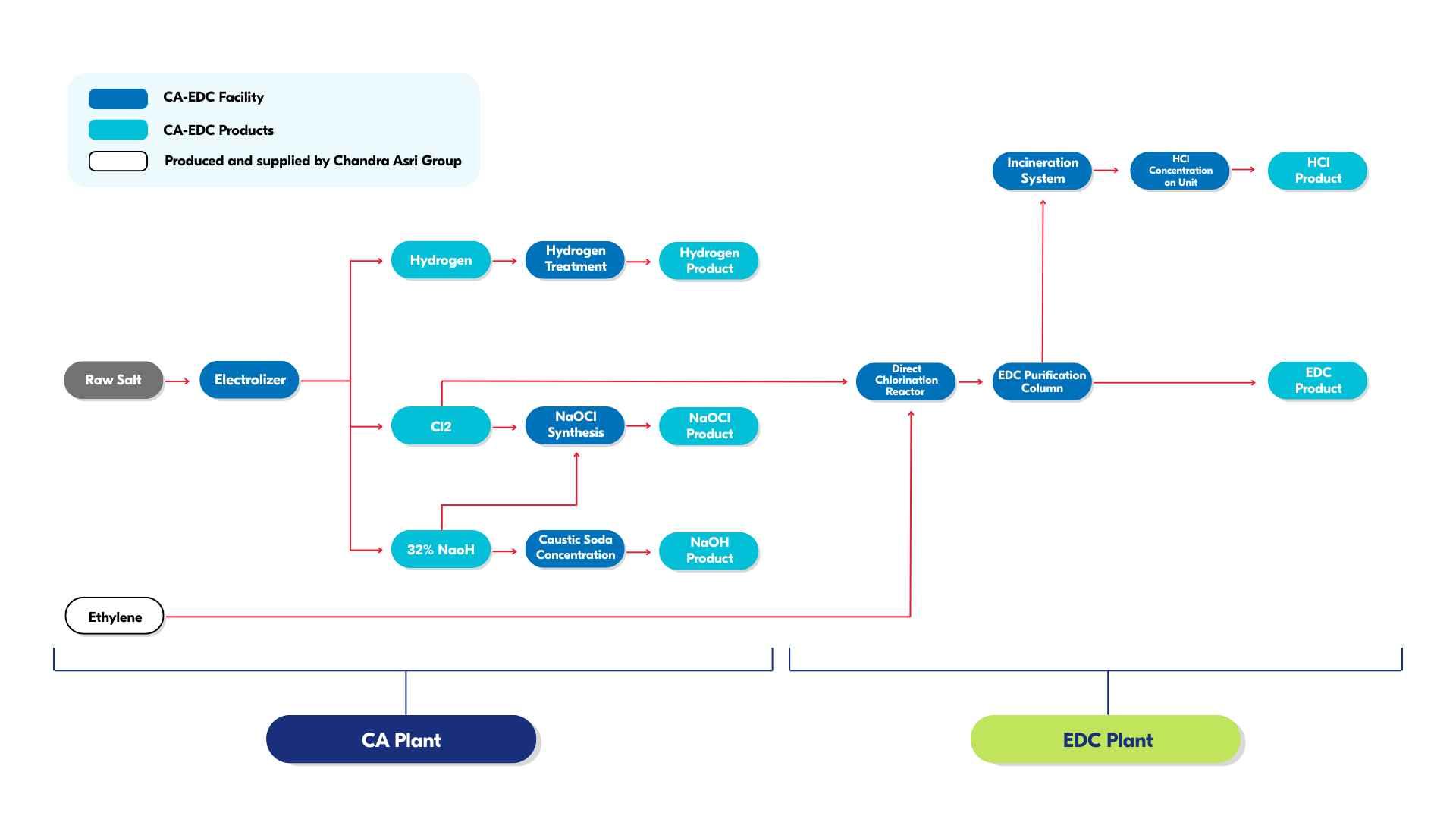

Chandra Asri Group is Indonesia's leading chemicals company, operating the country’s largest integrated petrochemical complex. We continue to grow organically through projects like the CA-EDC plant, which supports the EV ecosystem and key industries by producing caustic soda and ethylene dichloride.

As part of our regional expansion, together with Glencore, we acquired Shell Singapore Pte. Ltd. through our joint venture, CAPGC Pte. Ltd. The newly named Aster Chemicals and Energy Pte. Ltd. operates integrated facilities in Bukom and Jurong Island, including a refinery and an ethylene cracker unit.

Our operations are supported by a skilled team, on-site jetty, and tank farm, enabling efficient storage and logistics that enhance overall production reliability.

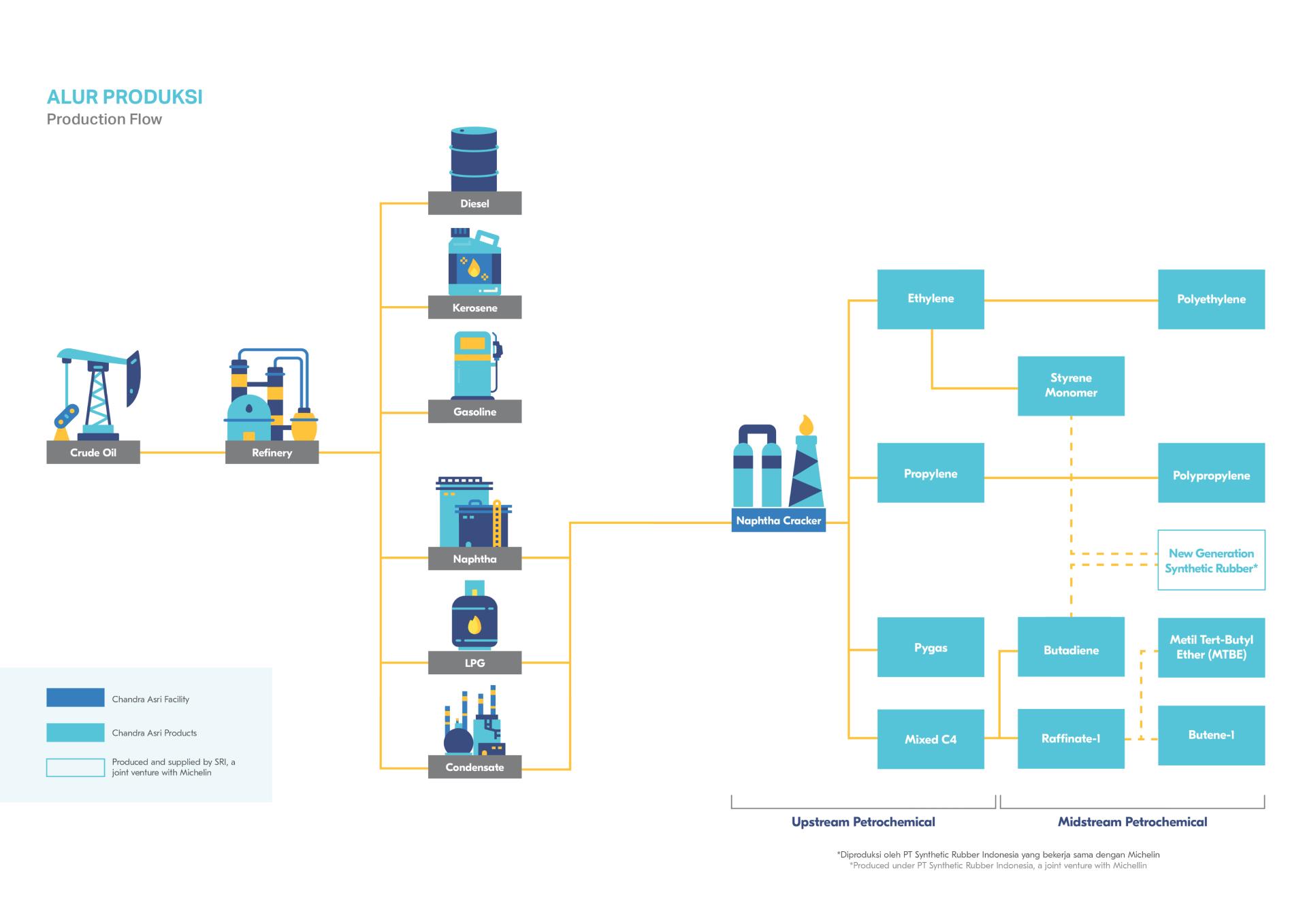

We pride ourselves on a meticulously designed production chemical flow that ensures precision, reliability, and optimal performance at every stage. Dive into the heart of our process to discover how we turn raw materials into high-quality products seamlessly.

Our Olefins plant is licensed by world renowned Lummus and KBR Technology. Our Naphtha Cracker mainly uses Naphtha and is capable of consuming alternative feedstock such as LPG and Condensate to produce Ethylene, Propylene, Pygas and Mixed C4 with annual production capacity of 900KTA, 490KTA, 418KTA, and 330KTA respectively.

Our 336KTA Polyethylene plants utilize two world-class technologies. One PE production train with capacity of 200KTA is licensed by Univation Technologies, a joint venture of ExxonMobil Chemical Company and The Dow Chemical Company, (originally was licensed by Union Carbide Corporation, UNIPOL) and are capable of producing both linear-low and high density Polyethylene resins. The second PE production train has a capacity of 136KTA and is licensed by Showa Denko KK which boasts Japan's bimodal high density Polyethylene technology. In 2019, new Polyethylene plant was inaugurated with additional capacity of 400KTA brings the total capacity to 736KTA.

Our 590KTA Polypropylene plants consist of three trains are licensed by W. R. Grace & Co. (originally was licensed by Union Carbide Corporation, UNIPOL) and are capable of producing a variety of Polypropylene resins including Homopolymer, Random Copolymer and Impact (Block) Copolymer.

The Company operates plants consist of two trains with capacity of 340KTA which using both Mobil-Badger Technology and Lummus Technology. The Company is ideally positioned to meet the demand of local and regional downstream industries. The Company had also acquired majority ownership of PT Redeco Petrolin Utama (RPU) in 2012. RPU was established in 1980 and is engaged as an intermediate bulk-storage tank terminal and jetty management services for chemical products. RPU is also handling refined petroleum products for local and international oil companies.

We operates a 137KTA plant licensed by Lummus/BASF Technology. This plant consumes Mixed C4 from our Naphtha Cracker to produce high quality Butadiene and Raffinate-1. Butadiene is a critical feedstock to produce synthetic rubber which is one of the raw materials for tires production.

In supporting our business operations, we own on-site warehouses next to PE & PP plants, and satellite warehouses in Surabaya and Solo. Other on-site supporting utilities include gas turbine generator, steam turbine generator, boiler, water treatment facility, water cooling system, and firefighting system.

The Company operates the first MTBE (Methyl Tert-butyl Ether) and B1 (Butene-1) plants in Indonesia with production capacities of 128KTA and 43KTA respectively. Licensed by Lummus Technology, MTBE & B1 plants operate to supply domestic octane boosters, which are currently imported.

Aster Jurong Island spans more than 60 hectares and produces key chemical products such as ethylene oxide, ethoxylates, styrene monomer, and propylene oxide.