20-09-2025

What Is Cold Chain Logistics & Its Role in Supply Chain

Did you know? Fresh ingredients, such as fish and vegetables, as well as chemicals like phenol and acetic acid, are specially delivered. The logistics management for these materials is referred to as the cold chain.

The cold chain is a shipping method aimed at maintaining product quality due to its perishable nature. To learn more about the ins and outs of cold chain logistics, read this article to the end!

What Is Cold Chain Logistics?

Cold chain logistics is a supply chain management system that uses specialized cooling technology and is designed exclusively for temperature-sensitive products such as perishable goods, medicines, vaccines, chemicals, and more.

The main purpose of cold chain logistics is to maintain a consistent temperature throughout the storage and shipping process. That way, these products remain intact and fresh, and their quality is safely guaranteed.

The cold chain method has undergone a series of innovations, resulting in several cooling technology options, including:

- Dry ice to keep products frozen for a long period.

- Ice packs for medical and pharmaceutical materials.

- Liquid nitrogen is used to maintain the temperature of biological samples, such as organs and tissues.

- Reefer or transport equipment with temperature and air circulation control technology.

- Quilts or ice wraps are placed over products to maintain their temperature.

- Insulated containers with cooling units that are able to preserve product temperature.

- Cold storage warehouses maintain consistent humidity and temperature levels to extend product shelf life.

- Temperature monitoring systems that can detect errors that may compromise product quality.

Since the logistics industry revolution in the 1950s, cold chain logistics has expanded quickly due to the constantly changing cold chain technology. According to Statista, in 2024, cold chain logistics revenue reached USD 364 billion.

Read also: Understanding Free On Board (FOB), Types, and Advantages

How Important Is Cold Chain Logistics for the Industry?

Cold chain logistics is implemented in some products for several reasons, such as:

1. Maintaining the Quality

Temperature-sensitive products have a high risk of damage during storage and shipping. They can rapidly deteriorate due to the growth of bacteria and microbes. This surely can reduce sales opportunities and profits for the company.

Therefore, warehouses, retail locations, and vehicles used for these products must be able to maintain accurate temperatures to extend their shelf life. One example of a product that requires controlled temperature to preserve its quality is fresh meat, whether fish or livestock meat.

2. Optimizing Operational Efficiency

We can mitigate the risk of damage and reduce the cost of replacement and repairs, as well as minimize waste. As a result, operational processes can continue to run efficiently.

3. Compliance with Regulations

The supply chain management process, from production to distribution, has its own regulations and standards. Therefore, proper cold chain management can help mitigate losses caused by product damage and assist companies in complying with quality assurance protocols.

Some regulations governing the cold chain include ISO 22000, which regulates food safety; the Good Distribution Practice (GDP) guidelines that ensure temperature-sensitive products receive proper handling during distribution; and many more.

4. Improving Safety

Cold chain warehouses and transportation equipment can maintain stable temperatures, preventing the growth of harmful microorganisms. Consequently, food or medicine remains safe from causing illness or food poisoning.

5. Reducing Waste

A proper and effective cold chain logistics mechanism will reduce waste from damaged products. As a result, cash flow remains stable, and the company avoids wasting resources that could potentially harm the environment.

6. Increasing Customer Satisfaction

Reliable cold chain delivery is able to boost customer satisfaction because they receive the products in optimal condition. This benefit can also enhance your company's reputation.

Read also: What Are FPSO Vessels? How They Work and Their Advantages

Components of Cold Chain Logistics

To maintain the quality of temperature-sensitive products and stay competitive in cold chain logistics, you can equip the following cold chain components:

1. Cold Storage Rooms and Warehouses

Cold storage rooms and warehouses serve as key foundations of cold chain logistics, as products are stored there before distribution

Cold storage warehouses typically use advanced technologies, such as real-time temperature monitoring devices, humidity controllers, air ventilation, and floor-to-ceiling insulation, to maintain the conditions precisely.

Regarding cold chain logistics warehousing, Chandra Asri Group provides logistics solutions through PT Chandra Cold Chain, which operates both dry and cold storage facilities strategically located across Java and Cilegon.

2. Temperature-Controlled Packaging

During delivery, weather and temperature may fluctuate. Therefore, products also need to be packaged with technology that is able to absorb or release heat and maintain stable product temperatures.

Some common types of packaging used in cold chain shipping include gel packs, water blankets, insulated pouches, EPS molded coolers, plant-based wraps, insulated polystyrene coolers, as well as insulated covers and pallets.

3. Transportation Modes with Cooling Units

In addition to warehouses and packaging, transportation modes must be equipped with a temperature control system and special cooling units. Common examples include refrigerated trucks, reefer ships, and refrigerated containers.

4. Regulations

Companies must comply with existing regulations to prevent legal action. Internationally, applicable regulations include ISO 9001 certification for quality assurance and transportation protocols such as ATP Certification for transporting perishable food.

In Indonesia, you can refer to SNI ISO 23412:2020 on controlled-temperature delivery services and SNI 9300:2024 on cold chain personnel competencies. These regulations are developed by the Badan Standardisasi Nasional (BSN).

5. Quality Assurance

An effective quality assurance process can maintain the quality of shipped products. You can conduct real-time monitoring, perform inspections at every stage of the supply chain, and provide training for workers who directly handle the products.

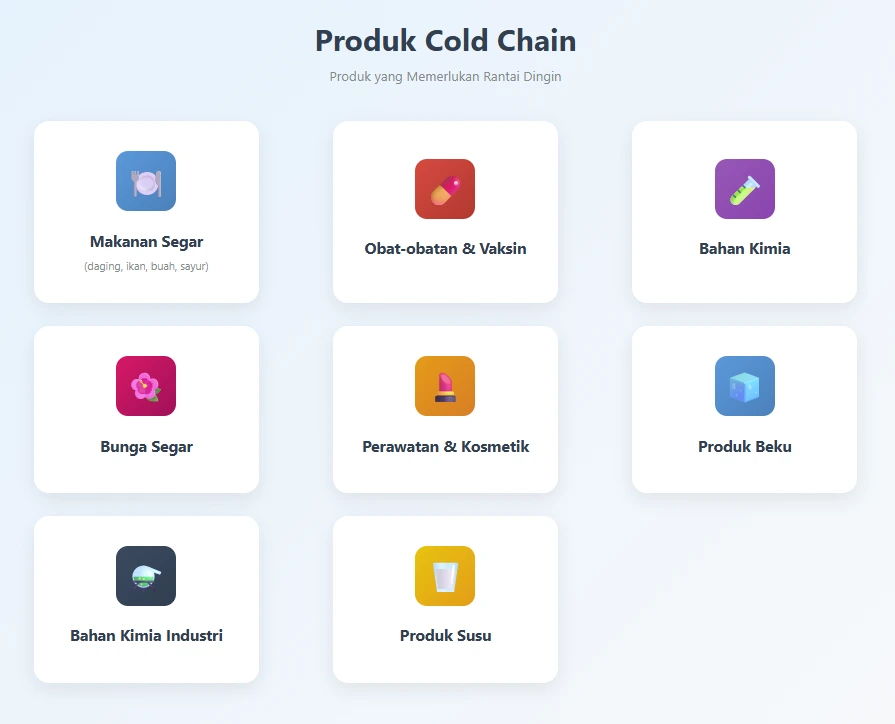

Products That Need Cold Chain Logistics

Products that require cold chain methods usually need low temperatures to prevent damage. Here are some products that require cold chain logistics:

- Fresh food (meat, fish, fruits, and vegetables).

- Medicines and vaccines.

- Chemicals.

- Fresh flowers.

- Body care and cosmetic products.

- Frozen products.

- Industrial chemicals.

- Dairy products.

That concludes the information you need to know about the cold chain logistics. The cold chain is one of the essential aspects of supply chain management to ensure perishable foods can be transported safely.

One type of product that requires special handling is chemicals. If you are planning to ship chemicals, do not worry because Chandra Asri Group has the solution.

Through PT Chandra Shipping International and PT Marina Indah Maritim, we operate nine vessels with a capacity of up to 106,650 DWT. This number continues to grow along with ongoing acquisitions.

In addition, we also provide warehousing services through PT Chandra Cold Chain and a fleet of 155 trucks operated by PT SCG Barito Logistics.

Read also: 9 Dangerous Goods and a Guide to Transport Them Safely

.png&w=3840&q=75)

.png&w=3840&q=75)